Shantou Ultrasonic was founded in 1957 and is a leading professional manufacturer of non-destructive testing equipment and transducers in China. After nearly 70 years of technological accumulation and innovative development, the company has formed a profound technical foundation and exquisite craftsmanship level in the field of ultrasonic testing. With outstanding product innovation capabilities, stable quality performance, and a comprehensive service system, the company has won widespread recognition in the industry. In the past 70 years, Shantou Ultrasonic has successively overcome more than 20 key technologies that fill the domestic gap, including the first generation of ultrasonic flaw detectors and transducers, analog and digital B-ultrasound rail flaw detectors, fully focused 3D phased array imaging equipment, and ultra-high frequency ultrasound. It continues to lead the industry's technological progress and is praised by users as the "first ultrasonic company in China".

Pioneered real-time 3D TFM (Total Focusing Method) technology in China, we offer a comprehensive product matrix that includes portable/benchtop systems, automated core modules, and customizable instruments supporting secondary development. Our solutions serve a wide range of industries, such as special instrument inspection, thermal power, wind power, railways, shipbuilding, and aerospace, delivering advanced ultrasonic testing capabilities to diverse industrial needs. STNDT successfully applied 3D technology to ultrasonic NDT, delivering simple, efficient, stable, and reliable inspections.

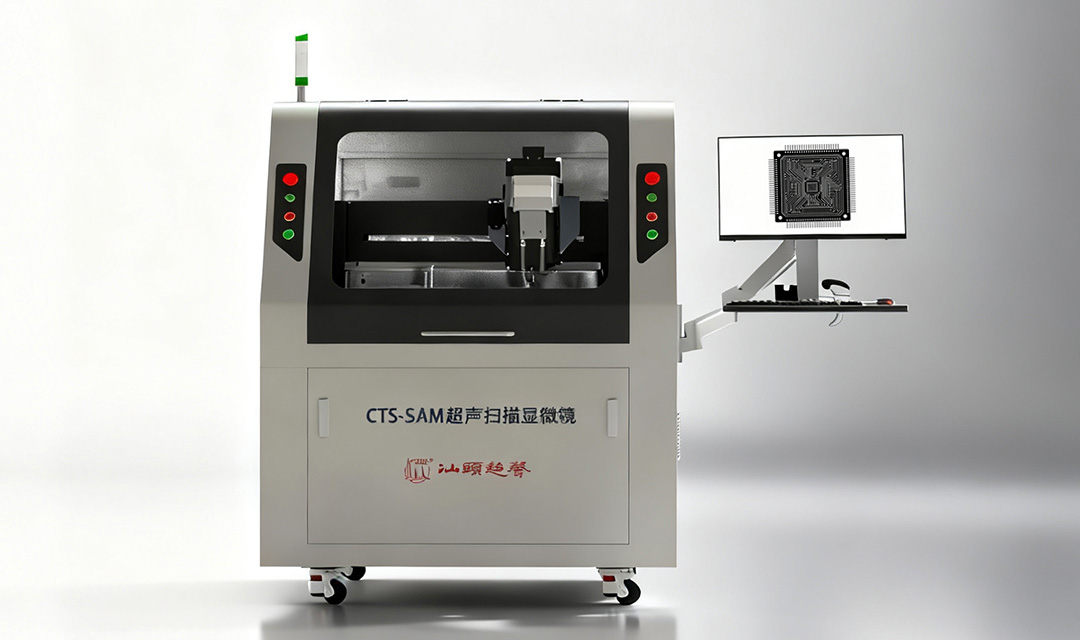

Our portfolio delivers a complete 20MHz–500MHz ultrasonic system solution, including main units and transducers, with core components featuring specially designed spike pulsers for high-frequency (HF) transducers. These pulsers offer a 1.2ns pulse width, adjustable voltage from -105V to -220V, and optimized performance for ultra-high-frequency (UHF) probes, serving as a premium domestic alternative to imported solutions (e.g., replacing the D*R500 series). Our systems support customizable configurations for Scanning Acoustic Microscopy (SAM), high-frequency C-scan testing, multi-channel parallel testing, and multi-channel phased array testing—enabling versatile, high-precision inspection across advanced applications.

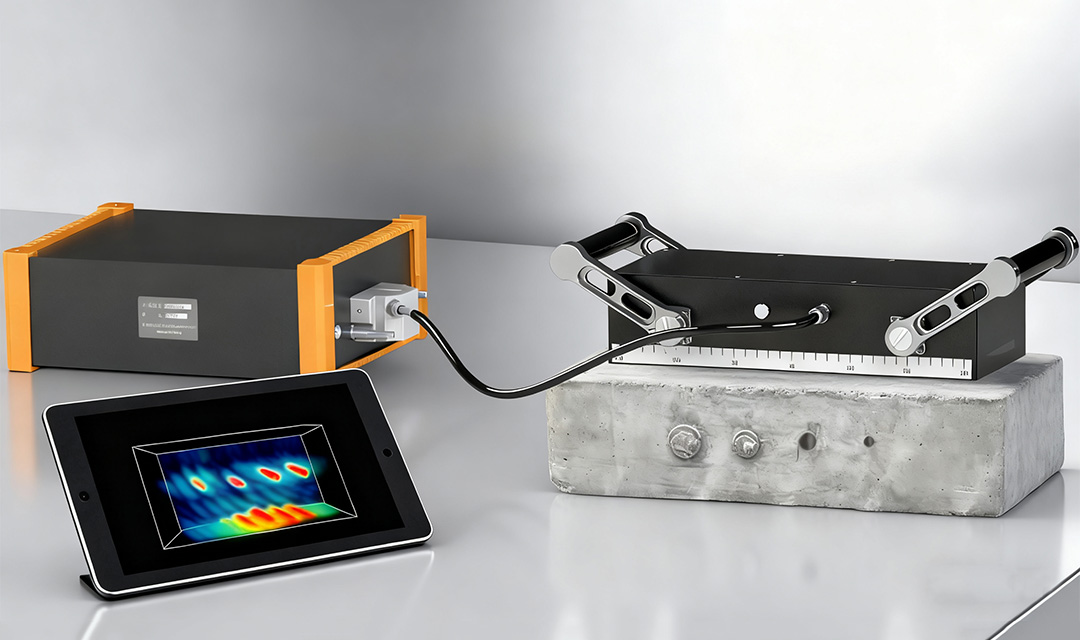

Our instrument operates with a broad frequency range extending down to 10 kHz and supports driving voltages up to 3000V. It features advanced signal generation capabilities, producing multi-cycle frequency-variable excitation signals and customizable FM square waves with arbitrary ratios. Specifically engineered for nondestructive testing and evaluation (NDT/NDE), this system demonstrates exceptional performance when inspecting highly attenuative materials—including concrete, rubber, timber, and composite structures—while also enabling specialized techniques such as air-coupled testing, electromagnetic acoustic transducer (EMAT) methods, and nonlinear ultrasonic testing.

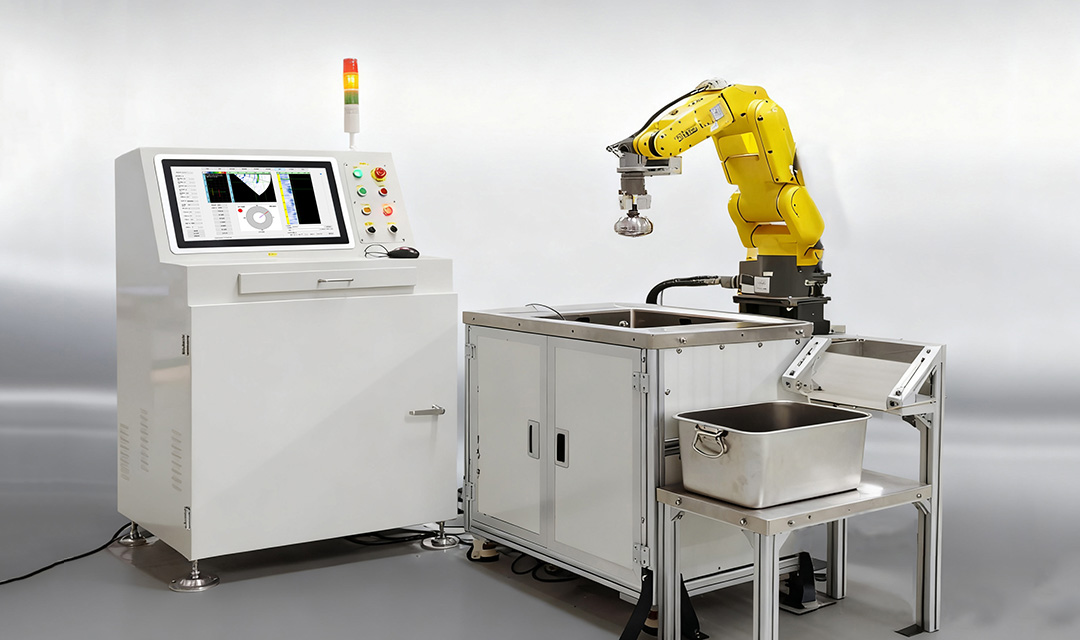

Engineered for high-precision, high-volume inspection scenarios, our modular hardware and intelligent software platform enables seamless production line integration. The system features core components including multi-axis motion control systems, high-speed data acquisition modules, AI-powered defect analysis software, and custom fixture solutions. Specifically developed to meet stringent efficiency and zero-defect requirements, this solution serves critical industries such as aerospace, new energy, and rail transit -- delivering unmatched reliability for mission-critical quality control applications.

Leveraging our independently developed core technology system, we provide customers with customized services spanning product R&D, design, manufacturing, and post-production support and maintenance. Supported by a fully self-controlled technology platform, our company delivers comprehensive tailored solutions for automation instrument manufacturers, system integrators, cloud processing platform data acquisition terminals, critical execution nodes in industrial production lines, and research institutions. These solutions encompass transducers, testing instruments, and system integration.

With a 70-year legacy of ultrasonic technology expertise, our portfolio spans from fundamental testing to professional applications. Engineered for exceptional stability, user-friendly operation, and industry-specific customization, our solutions serve diverse sectors including pressure vessel inspection, cast/forged components evaluation, and weld quality assessment - delivering tiered solutions from entry-level to industrial-grade systems.

Leveraging electromagnetic ultrasonic (EMAT) and multi-frequency eddy current technologies, our products enable non-contact, couplant-free inspection – ideal for high-temperature, high-speed testing, and defect detection through coatings/rust layers. These solutions overcome the limitations of conventional ultrasonic methods on rough surfaces and in extreme environments.

A comprehensive range of high-performance probe solutions covering all technologies, featuring proprietary core materials and manufacturing processes to ensure signal consistency. Our portfolio offers specialized designs from normal to extreme environment applications, with full customization capabilities including active probes and smart networked probes for in-service Structural Health Monitoring (SHM) inspection.

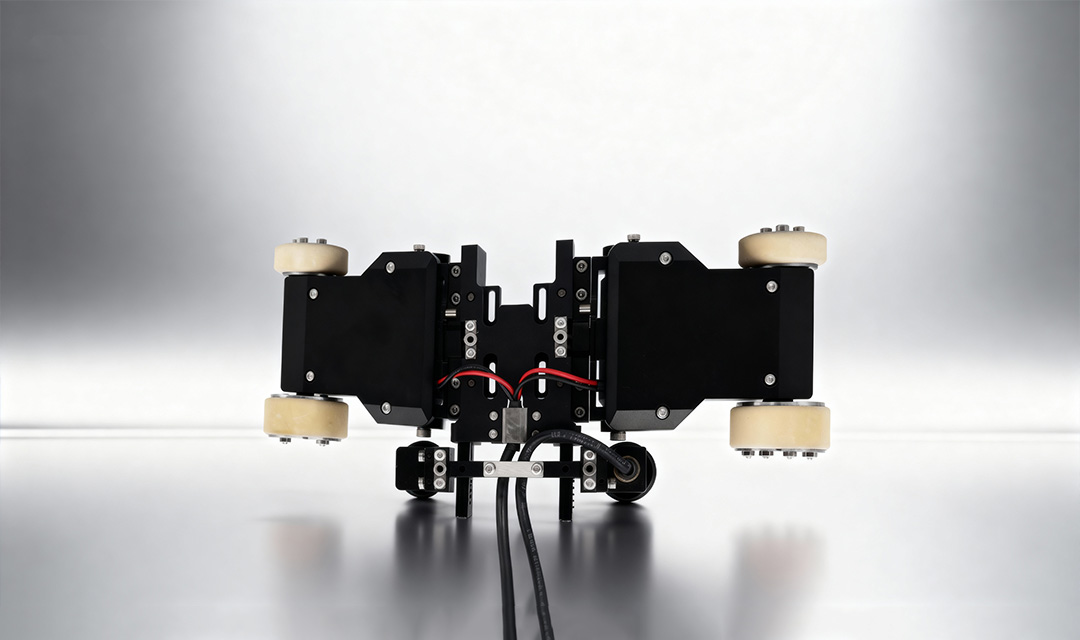

From manual precision scanning to six-axis robotic automated path planning, our solutions integrate encoded positioning, visual grounding, immersion systems, and calibration blocks to ensure repeatable, standards-compliant inspection results, being compatible with ultrasonic instrument to achieve the traceable testing.